What are Screw Pile Caps

Screw pile caps are attachments or fittings placed on top of screw piles, which are a type of deep foundation used to support structures like buildings, bridges, and piers. These caps are essential components that help to distribute the load from the structure evenly across the screw piles, enhancing stability and strength.

Screw piles themselves are long steel shafts with helical flanges or blades that are screwed into the ground. The design allows for quick installation and immediate load-bearing capabilities. The caps, typically made of steel or concrete, are attached to the upper end of these piles and provide a secure connection point for the structure above.

The specific design and material of a screw pile cap can vary based on the application and the load requirements. Some caps are designed to allow for adjustments to ensure the pile aligns properly with the structural components it supports. These caps are crucial for ensuring the long-term performance and safety of the foundation system.

Contact Us for a Quote Today

How Do Screw Pile Caps Attach?

Screw pile caps are fabricated in a wide variety of shapes and forms to best match the primary structure of whatever the screw pile is intended to support. Much like a structural adaptor, joining one side to the supported structure and the other to the helical pile’s shaft. This in turn transfers the load from the supported structure to the screw pile cap, then to the pile shaft, and into the soil via the screw pile’s helix.

Pile caps can simply sit on a pile shaft under the forces of gravity, or if uplift loads are of concern, caps may be bolted or even welded in high-stress applications.

Types of Pile Caps & Their Applications

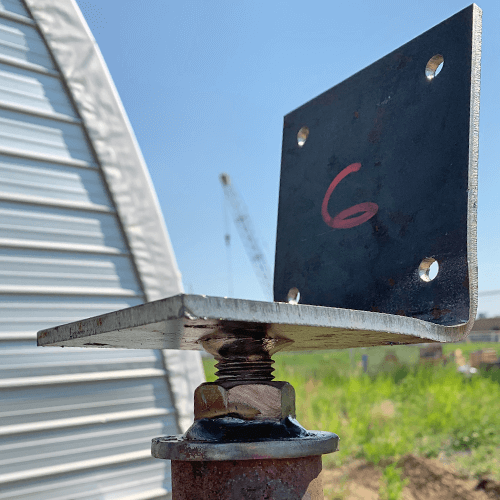

Standard Flat Cap

A standard flat cap is the most commonly used pile cap because of its simple design. A flat cap, as its name implies, is a flat plate with pre-cut bolt holes that mounts on top of a screw pile’s shaft. Because the flat cap is simply a flat plate, it can be bolted or welded to any primary structure of whatever the screw pile is used to support.

Additionally because of their low profile flat caps are used to support sidewalks, driveways and concrete slabs

Adjustable Pile Caps

Adjustable Screw Pile Caps have a threaded shaft, which allows for the adjustment of height by extending a threaded portion that is part of the screw pile cap. Despite there being a variety of adjustable cap designs available, most adjustable caps require unloading the structure and turning a non-fixed base plate either up or down along the cap’s threaded portion. The drawback to adjustable screw pile caps is that they are limited for use in light-duty applications. This is due to the limited structural strength of the cap’s threaded section.

Adjustable caps are most commonly used on uncovered decks. Having adjustable caps to support a laminated deck beam can make deck construction easier, as it often eliminates the need to cut vertical posts to height. Also, the deck’s height can be adjusted after it has been built to fine-tune the drainage angle or correct the deck’s height if the home it is attached to happens to settle over time.

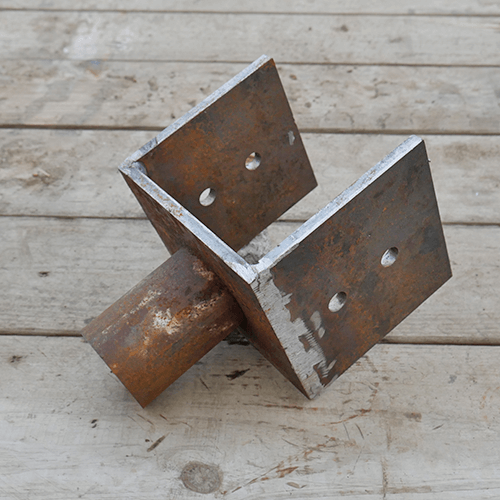

Post Support Saddle Bracket Cap

The saddle bracket cap has a “U” shaped bracket made to accommodate either a 4” or 6” wooden post. Saddle bracket caps are useful to connect wooden structures supported by posts like pergolas or three season rooms. The upright portions of the pile caps bracket are pre drilled to allow lag bolts to be used to fasten the wooden post structure to the pile cap.

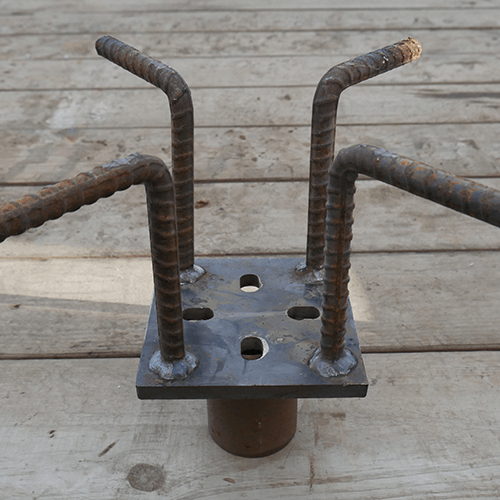

Rebar Pile Caps

Specifically made for concrete grade beams, the rebar cap has angled rebar extending from the top of the cap plate. This rebar attached to the cap allows for the reinforcing bars to be connected using rebar tie wire. Tying the rebar reinforcing structure directly to the pile cap makes for a more solid and stable grade beam after the concrete has been poured.

Custom Fabrication

Though most structural applications can be supported using any of the generic screw pile caps available, sometimes a situation may arise where a pile cap needs to be custom fabricated to meet a unique requirement. Fortunately, pile manufactures can custom fabricate pile caps to meet nearly any specified shape and load capacity. The downside to custom caps is there can be an increased cost and lead time. However, in the occasional circumstance having the correct pile cap specially made is well worth it.

Have Questions?

If you are unsure about which generic screw pile cap is best for your construction project or if you think you may require custom-fabricated pile caps, contact the Calgary Screw Pile Pros and feel free to ask. Our team has seen it all and can happily answer any questions you may have.